Are you wondering how to maintain the hydraulics system of a skid steer? Well, you’ve come to the right place! In this article, we’ll explore the essential steps you need to know to keep your skid steer’s hydraulic system in tip-top shape.

Maintaining a skid steer’s hydraulic system is crucial to ensure its optimal performance and longevity. Regular maintenance helps prevent costly repairs and ensures the smooth operation of your skid steer. So, let’s dive in and discover the secrets to maintaining your skid steer’s hydraulics system like a pro.

Proper maintenance of your skid steer’s hydraulic system is not only important for its efficiency but also for your safety. By understanding the ins and outs of hydraulic system maintenance, you’ll be able to tackle minor issues and keep your skid steer running smoothly for years to come. Let’s get started!

- Inspect the Hydraulic Fluid: Check for any signs of contamination or low fluid levels.

- Replace the Hydraulic Filter: Regularly change the filter to prevent debris from damaging the system.

- Monitor Hydraulic Hoses: Look for any signs of wear or leaks, and replace if necessary.

- Clean the Reservoir: Remove any dirt or debris from the reservoir to avoid clogging the system.

- Keep the System Cool: Ensure the hydraulic system doesn’t overheat by checking the cooling components regularly.

How to Maintain the Hydraulics System of a Skid Steer?

Welcome to our comprehensive guide on maintaining the hydraulics system of a skid steer. Skid steers are versatile machines used in a wide range of industries, from construction to agriculture. The hydraulic system is a crucial component that allows the skid steer to perform various tasks efficiently. In this article, we will provide you with detailed information on how to properly maintain the hydraulics system to ensure optimal performance and longevity of your skid steer.

1. Understanding the Hydraulics System

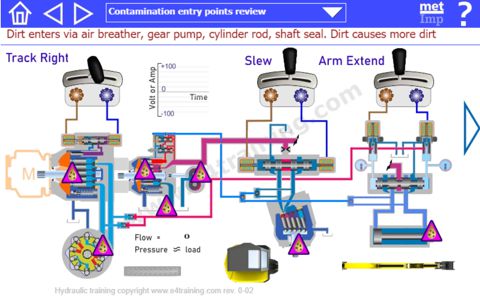

The first step in maintaining the hydraulics system of a skid steer is to gain a basic understanding of how it works. The hydraulics system uses hydraulic fluid, a pump, valves, and actuators to transfer power and enable the machine to control attachments and perform tasks. It is important to familiarize yourself with the different components of the system and their functions. Refer to the skid steer’s manual for detailed information specific to your machine.

Regularly inspect the hydraulic hoses, fittings, and connections for any signs of wear, leaks, or damage. Replace any damaged components immediately to prevent further issues and ensure the proper functioning of the hydraulics system. It is also essential to pay attention to the hydraulic fluid level and quality. Contaminated or low fluid levels can affect the system’s performance and lead to expensive repairs.

In addition to visual inspections, it is recommended to have the hydraulics system checked by a professional technician at least once a year. They can perform more in-depth inspections and tests to identify any potential issues or maintenance needs.

2. Regular Maintenance Tasks

Maintaining the hydraulics system of a skid steer requires regular maintenance tasks to ensure optimal performance and prevent costly breakdowns. Here are some essential maintenance tasks to keep in mind:

- Fluid Inspection and Replacement: Check the hydraulic fluid regularly and replace if necessary. Follow the manufacturer’s guidelines for the recommended type of fluid and intervals for replacement.

- Filter Replacement: Replace the hydraulic filters according to the manufacturer’s recommendations. Filters help remove contaminants from the fluid, ensuring smooth operation of the system.

- Seal and O-ring Inspection: Inspect the seals and O-rings in the system for signs of wear or damage. Replace them as needed to prevent leaks and maintain system integrity.

- Cleaning: Keep the hydraulic components clean by removing dirt, debris, and other contaminants. Use a soft cloth or brush to clean the exterior surfaces and take care not to damage any sensitive parts.

- Lubrication: Properly lubricate moving parts and fittings as recommended by the manufacturer. This helps reduce friction and wear, enhancing the lifespan of the system.

By performing these regular maintenance tasks, you can ensure that the hydraulics system of your skid steer remains in good working condition and minimize the risk of breakdowns or costly repairs.

3. Troubleshooting Common Issues

Despite regular maintenance, issues may still arise with the hydraulics system of your skid steer. Knowing how to troubleshoot common issues can help you identify and resolve problems promptly. Here are some common issues and possible solutions:

Low Hydraulic Power or Slow Operation

If you notice a decrease in hydraulic power or slow operation of attachments, check the hydraulic fluid level. If the fluid level is low, refill it to the recommended level. However, if the fluid level is normal, it could indicate a problem with the pump, valve, or other components. In such cases, it is best to consult a professional technician for further assistance.

Unusual Noises or Vibrations

Unusual noises or vibrations can be an indication of air trapped in the hydraulic system or worn-out components. Bleeding the system to remove air or replacing worn-out parts may help resolve the issue. If the problem persists, it is advisable to seek professional help to prevent further damage.

Leaking Hydraulic Fluid

If you notice hydraulic fluid leaking from the system, locate the source of the leak and inspect the affected component. Tighten any loose connections or replace damaged hoses, seals, or fittings. It is important to address hydraulic fluid leaks promptly as they can lead to system failure and potential safety hazards.

Remember to always follow safety procedures and manufacturer’s guidelines when working on the hydraulics system of your skid steer. If you are unsure or uncomfortable with performing any maintenance or troubleshooting tasks, it is best to consult a qualified technician.

Additional Maintenance Tips for Skid Steer Hydraulics System

Now that we have covered the basics of maintaining the hydraulics system of a skid steer, let’s explore some additional tips to ensure its optimal performance and longevity:

1. Maintain Cleanliness

Keep the skid steer and its hydraulics system clean to prevent dirt, dust, and debris from entering and causing damage. Regularly clean the exterior surfaces, air vents, and cooling fins to promote proper airflow and cooling.

When working in dusty or dirty environments, consider using covers or protective shields for the hydraulic components to minimize the risk of contamination.

2. Check for Leaks

Regularly inspect the hydraulics system for any signs of leaks. Pay attention to fluid drips, puddles, or wet spots around hoses, fittings, and cylinders. Promptly address any leaks to prevent further damage and maintain the integrity of the system.

3. Use the Right Fluid

Always use the manufacturer-recommended hydraulic fluid for your skid steer. Using the wrong type of fluid can lead to system malfunctions, damage, and voiding of warranties. Refer to the machine’s manual or consult a professional for guidance.

Ensure that the hydraulic fluid is clean and free from contaminants. Contaminated fluid can cause clogs, damage components, and impair overall system performance. Regularly check the fluid for particles, discoloration, or foaming, and replace if necessary.

Regular Maintenance Ensures Optimal Skid Steer Performance

By following the maintenance tips and guidelines provided in this article, you can ensure that the hydraulics system of your skid steer remains in excellent condition, enabling optimal performance and longevity. Regular inspections, proper fluid levels, timely repairs, and adherence to manufacturer’s recommendations are key to maintaining a healthy hydraulics system. Remember, a well-maintained skid steer will not only perform better but also save you time and money in the long run.

Key Takeaways: How to Maintain the Hydraulics System of a Skid Steer?

- Regularly check hydraulic fluid levels and ensure they are within the recommended range.

- Clean the hydraulic filters to prevent debris from clogging the system.

- Inspect hoses and fittings for any signs of leaks or damage and promptly replace if necessary.

- Keep the hydraulic system well-lubricated by following manufacturer’s recommendations for grease or oil.

- Schedule routine maintenance and inspections to identify and address any potential issues before they escalate.

Frequently Asked Questions

When it comes to maintaining the hydraulics system of a skid steer, there are key considerations to keep in mind. Here are some commonly asked questions about maintaining the hydraulics system of a skid steer, along with their answers.

Why is regular hydraulic fluid maintenance important?

Regular hydraulic fluid maintenance is vital for the smooth operation and longevity of the skid steer’s hydraulics system. Over time, hydraulic fluids can become contaminated with dirt, debris, and moisture. These contaminants can cause damage to the hydraulic components, leading to reduced performance and potential failure. By regularly changing the hydraulic fluid and filter, you can remove these contaminants and ensure optimal performance.

Furthermore, hydraulic fluid degrades over time due to temperature fluctuations and oxidation. It loses its viscosity and lubrication properties, which can result in increased friction and wear in the hydraulic system. By maintaining regular hydraulic fluid changes, you provide fresh fluid to the system, ensuring smooth operation and protecting the components from premature wear.

How often should I change the hydraulic fluid in my skid steer?

The frequency of hydraulic fluid changes in a skid steer depends on several factors. Generally, it is recommended to change the hydraulic fluid every 1,000 to 2,000 operating hours or at least once a year, whichever comes first. However, certain conditions may necessitate more frequent changes. If the skid steer operates in demanding environments, such as in dusty or dirty conditions or at high temperatures, more frequent changes may be needed to maintain optimal performance.

It’s also important to monitor the condition of the hydraulic fluid regularly. If you notice discoloration, a burnt smell, or the presence of debris, it is a sign that the fluid should be changed even if it hasn’t reached the recommended operating hours. Always refer to the manufacturer’s guidelines for the specific maintenance schedule for your skid steer model.

What steps can I take to prevent hydraulic system contamination?

Preventing hydraulic system contamination is crucial for the proper functioning of a skid steer. Here are some steps you can take to minimize contamination:

1. Keep the area around the hydraulic reservoir and fill cap clean to prevent dirt and debris from entering the system.

2. Use a proper breather cap or filter to prevent moisture and airborne contaminants from entering the reservoir.

3. Inspect all hydraulic connections regularly for signs of leaks, which can introduce contaminants into the system.

4. Clean the hydraulic system before performing maintenance work to prevent introducing external contaminants into the system.

5. Use clean tools and equipment when working on the hydraulics system to avoid introducing debris.

How can I check for hydraulic system leaks?

Checking for hydraulic system leaks is an essential part of hydraulic system maintenance. Look out for the following signs that may indicate a hydraulic system leak:

1. Visible fluid drips or puddles underneath the skid steer.

2. Sudden or unexplained drops in hydraulic fluid levels.

3. Unusual noises, such as hissing or whistling sounds, coming from the hydraulics system.

4. Loss of hydraulic power or reduced performance.

5. Presence of hydraulic fluid on hoses, fittings, or other components.

If you suspect a hydraulic system leak, it’s important to identify and fix the source of the leak promptly. Continuing to operate the skid steer with a leak can lead to further damage and potentially costly repairs. Consult the skid steer’s manual or a professional technician for guidance in locating and resolving hydraulic system leaks.

What are some tips for maintaining hydraulic hoses?

Proper maintenance of hydraulic hoses is essential for the reliable functioning of a skid steer’s hydraulics system. Here are some tips to keep in mind:

1. Regularly inspect the hoses for signs of wear, such as cuts, abrasions, bulges, or exposed reinforcement.

2. Replace any damaged hoses immediately to avoid potential leaks or failures.

3. Protect hoses from excessive heat, UV exposure, and sharp edges that can cause damage.

4. Routinely clean the hoses to remove dirt and debris that can accelerate wear.

5. Avoid twisting or bending the hoses beyond their recommended limits to prevent damage to the reinforcement or inner tube.

Following these tips will help extend the lifespan of hydraulic hoses, minimize the risk of leaks, and ensure the safe and efficient operation of the skid steer’s hydraulics system.

Skid Steer Solutions Quick Tips: Hydraulic Back Pressure

Summary

Keeping the hydraulics system of a skid steer in good condition is important for its performance. Regularly checking the fluid levels and filters, and replacing them when necessary, is essential. Maintaining clean fluid and preventing contamination is crucial to prevent damage to the system. Additionally, inspecting hoses and seals for leaks and wear, and addressing any issues promptly, will help to extend the lifespan of the hydraulics system. Following these tips will ensure that your skid steer runs smoothly and efficiently.