Do skid steers have different drive systems? If you’ve ever wondered about these versatile machines, you’re in the right place. Skid steers are widely used in construction, agriculture, and landscaping due to their maneuverability and versatility. In this article, we’ll dive into the world of skid steers and explore the different drive systems they employ.

Skid steers are known for their ability to turn on a dime and navigate tight spaces with ease. But did you know that they can have different types of drive systems? From traditional mechanical systems to innovative hydraulic systems, skid steers offer a variety of options to suit different needs.

Whether you’re a skid steer enthusiast or simply curious about these powerful machines, we’ll walk you through the various drive systems available and help you understand their benefits and applications. Let’s strap in and embark on this exciting journey into the world of skid steer drive systems!

Skid steers indeed have different drive systems that cater to different needs. Common types include wheeled and tracked drive systems. Wheeled skid steers offer great maneuverability on smooth surfaces and are better for speed, while tracked skid steers excel in rough terrains with enhanced traction and stability. Additionally, some skid steers offer advanced drive systems like all-wheel drive or skid steer loader with 4-wheel steer, providing even greater versatility and performance. Understanding the different drive systems can help you choose the right skid steer for your specific requirements.

Do Skid Steers Have Different Drive Systems?

Skid steers are versatile machines commonly used in construction, landscaping, and agriculture. They are known for their compact size and maneuverability, making them ideal for tight spaces and rugged terrains. However, when it comes to their drive systems, there are different options available. In this article, we will explore the various drive systems used in skid steers, their benefits, and how they impact the machine’s performance.

Types of Drive Systems in Skid Steers

Skid steers can have different drive systems, and each system has its advantages and specific applications. Let’s take a closer look at the three main types:

All-Wheel Drive (AWD) Skid Steers

All-wheel drive skid steers, as the name suggests, distribute power to all four wheels simultaneously. This allows for better traction on slippery or uneven surfaces, making them ideal for challenging terrains. AWD skid steers have higher torque and can tackle heavy-duty tasks with ease. They are commonly used in industries such as construction and agriculture, where rough terrains require superior traction and stability.

Benefits of All-Wheel Drive Skid Steers:

- Enhanced traction and stability on uneven surfaces

- Higher torque for heavy-duty tasks

- Improved maneuverability in tight spaces

All-wheel drive skid steers are a reliable choice for demanding jobsites, offering the power and performance needed to get the job done efficiently.

Four-Wheel Drive (4WD) Skid Steers

Four-wheel drive skid steers, also known as four-track skid steers, provide increased stability and reduced ground pressure. They feature individual motors driving each wheel independently, allowing for better weight distribution and minimizing soil damage. 4WD skid steers are commonly used in landscaping and site preparation jobs, where preserving the integrity of the terrain is crucial.

Benefits of Four-Wheel Drive Skid Steers:

- Improved stability and reduced ground pressure

- Minimized soil damage and turf disturbance

- Optimized weight distribution for better maneuverability

Four-wheel drive skid steers are a popular choice for tasks that involve delicate surfaces or environmentally sensitive areas.

Pros and Cons of Different Drive Systems

Each drive system has its pros and cons, and choosing the right one depends on the specific requirements of the job. Let’s discuss the advantages and limitations of each drive system:

All-Wheel Drive (AWD)

Pros:

- Superior traction and stability on challenging terrains

- Higher torque for heavy lifting and pushing

- Excellent maneuverability in tight spaces

Cons:

- Higher initial cost compared to other drive systems

- Increased fuel consumption

- More maintenance requirements

Four-Wheel Drive (4WD)

Pros:

- Reduced ground pressure and soil damage

- Improved stability on rough terrains

- Optimized weight distribution for better control

Cons:

- Limited speed compared to other drive systems

- Less maneuverability in tight spaces

- Higher maintenance cost for individual wheel motors

After considering the pros and cons, it’s important to assess the specific needs of your project to determine which drive system will best meet your requirements.

Additional Considerations for Skid Steer Drive Systems

When selecting a skid steer drive system, it’s important to consider factors beyond the type of drive. Here are a few additional considerations:

Ground Conditions

The ground conditions play a crucial role in determining the best drive system for your job. If you’re working on slippery or uneven surfaces, an all-wheel drive skid steer may be the best choice for enhanced traction. On the other hand, if you’re working on delicate surfaces or areas where soil damage is a concern, a four-wheel drive skid steer can offer better control and minimize damage.

Job Requirements

Assessing the specific requirements of your job is essential in choosing the right drive system. Consider factors such as the weight of the loads you’ll be carrying, the terrain you’ll be working on, and any space limitations on the job site. This information will help you determine whether you need the higher torque of an all-wheel drive or the reduced ground pressure of a four-wheel drive.

Operator Experience and Preference

The experience and preferences of the skid steer operator should also be taken into account. Some operators may have a strong preference for a particular type of drive system based on their familiarity and comfort level. It’s important to factor in their expertise to ensure optimal performance and efficiency on the job.

In conclusion, skid steers do have different drive systems, including all-wheel drive and four-wheel drive. Each drive system offers its unique advantages and limitations, and choosing the right one depends on factors such as the ground conditions, job requirements, and operator experience. By carefully considering these factors, you can select the most suitable drive system for your specific needs, ensuring optimal performance and productivity.

Key Takeaways: Do Skid Steers Have Different Drive Systems?

- Skid steers can have different drive systems depending on the model and manufacturer.

- The two main types of skid steer drive systems are “tire” and “track.”

- Tire-drive skid steers are more common and suitable for general use on stable surfaces.

- Track-drive skid steers are better for rough terrains, slopes, and muddy conditions.

- The drive system affects the skid steer’s performance, maneuverability, and suitability for different applications.

Frequently Asked Questions

When it comes to skid steers, understanding their drive systems is crucial. Here are some common questions people have about skid steer drive systems.

1. What are the different types of drive systems in skid steers?

Skid steers typically have two types of drive systems: mechanical and hydrostatic. Mechanical drive systems rely on chains, gears, and sprockets to distribute power to the wheels. Hydrostatic drive systems, on the other hand, use hydraulic pumps and motors to control the speed and torque. Both systems have their advantages and are suitable for different applications.

Overall, mechanical drive systems are known for their durability and cost-effectiveness. They are commonly found in older skid steer models. On the other hand, hydrostatic drive systems provide smoother operation and better maneuverability. They are widely used in modern skid steers and offer more control over speed and power.

2. How does a mechanical drive system work in a skid steer?

A mechanical drive system in a skid steer utilizes chains and sprockets to distribute power to the wheels. The engine drives a main shaft, which is connected to the drive chains. These chains then rotate the sprockets, which are attached to each wheel.

As the sprockets rotate, they transfer power to the wheels, causing them to move. By controlling the speed and direction of the engine, operators can control the movement of the skid steer. This mechanical drive system is known for its simplicity, durability, and ease of maintenance.

3. How does a hydrostatic drive system work in a skid steer?

A hydrostatic drive system in a skid steer uses hydraulic pumps and motors to control the movement of the machine. The engine drives a hydraulic pump, which pressurizes hydraulic fluid. This pressurized fluid is then directed to hydraulic motors attached to each wheel.

By adjusting the flow of hydraulic fluid to the motors, operators can control the speed and direction of the skid steer. The hydrostatic drive system offers smoother operation, better maneuverability, and the ability to change speed and direction without shifting gears. It provides precise control over the machine, making it ideal for tasks that require agility and versatility.

4. Can skid steers have both mechanical and hydrostatic drive systems?

Skid steers can have either a mechanical drive system or a hydrostatic drive system, but it is rare for a skid steer to have both. Manufacturers typically design skid steers with one type of drive system to optimize performance and durability for specific applications.

That being said, some skid steers may offer a choice between mechanical and hydrostatic drive systems, allowing buyers to select the option that best suits their needs. However, the decision between the two drive systems often depends on factors like budget, intended use, and personal preference.

5. Which drive system is better for different applications?

The choice between a mechanical drive system and a hydrostatic drive system depends on the specific application. Mechanical drive systems are well-suited for heavy-duty tasks in rough terrains. They offer increased durability, require less maintenance, and are often more cost-effective.

On the other hand, hydrostatic drive systems excel in tasks that require precise control, agility, and maneuverability. They provide smoother operation, easy speed control, and the ability to change directions without shifting gears. This makes them ideal for tasks that involve tight spaces, delicate movements, and operating in challenging conditions.

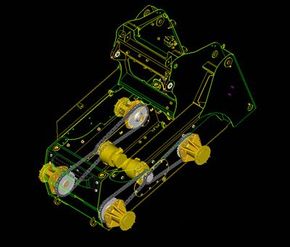

VBT Drive Mechanism in Skid Steer

Summary

Skid steers can have different drive systems, either wheeled or tracked. Wheeled skid steers are good for navigating smooth surfaces and are often faster, while tracked skid steers are more stable on uneven terrain.

Understanding the different drive systems can help you choose the right skid steer for your needs. Wheeled skid steers are great for construction sites with flat surfaces, while tracked skid steers are better for rough and muddy environments. Consider your job requirements and the type of terrain you’ll be working on to make the best choice.