If you’ve ever looked up at the sky and wondered about the different types of aircraft, you’ve probably come across terms like radial and vertical lift. But what do these terms actually mean? In this article, we’ll dive into the exciting world of aviation to explore the difference between radial and vertical lift.

We’ll start by understanding what radial lift means. Radial lift refers to the type of movement that an aircraft’s wings create during takeoff and landing. To put it simply, when an aircraft with radial lift takes off, its wings move in a circular motion, pushing the air downwards to generate lift. This type of lift is commonly seen in helicopters and some small aircraft, allowing them to take off and land vertically.

Now, let’s move on to vertical lift. As the name suggests, vertical lift refers to an aircraft’s ability to ascend and descend purely in a vertical direction. Unlike radial lift, which relies on circular motion, vertical lift is achieved through the use of specialized technology such as thrust vectoring or vertical takeoff and landing (VTOL) systems. This type of lift is commonly found in military jets and advanced helicopters, allowing them to hover, maneuver in tight spaces, and perform impressive aerial acrobatics.

So, whether it’s the circular motion of radial lift or the sheer vertical prowess of vertical lift, both types of aircraft offer unique capabilities and play an important role in our aviation landscape. Now that you have a better understanding of the difference between radial and vertical lift, let’s dig deeper into the fascinating world of aviation and explore the mechanics behind these incredible feats of engineering.

What’s the Difference Between Radial and Vertical Lift?

Radial and vertical lift are two terms commonly used in the field of engineering and mechanics. These concepts refer to different types of movements and have distinct applications in various industries. Understanding the difference between radial and vertical lift is crucial for engineers, mechanics, and anyone working with machinery. In this article, we will delve into the details of these two types of lifts, explain their mechanisms, applications, and highlight their key differences. So let’s get started!

Radial Lift: Mechanism, Applications, and Benefits

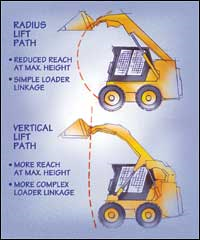

Radial lift refers to a type of lifting mechanism where the load moves in an arc or circle. This type of lift is commonly seen in machinery with hydraulic systems, such as excavators and backhoes. In a radial lift system, the pivotal point of the arm is closer to the operator, and the arm moves in an arc that is similar to the shape of a circle. As the arm lifts, the load is moved closer to the machine’s body.

One of the main advantages of radial lift is the increased lifting capacity it offers. The arc-shaped movement allows for a greater reach and lifting capability, making it ideal for heavy lifting tasks. It provides stability and better control when handling loads, especially in confined spaces or uneven terrain. Radial lift machines are commonly used in construction, agriculture, and mining industries where lifting heavy materials is a frequent requirement.

Another benefit of radial lift is the efficient use of power. Due to the lifting mechanism’s design, the radial lift machines require lesser power to operate, resulting in reduced fuel consumption and increased productivity. Additionally, the movement characteristics of radial lift machines make them more suitable for tasks that involve digging, pushing, and scooping materials.

Vertical Lift: Mechanism, Applications, and Benefits

Unlike radial lift, vertical lift refers to a lifting mechanism where the load moves straight up and down. This type of lift is common in machinery such as forklifts and scissor lifts. In a vertical lift system, the load is lifted vertically, maintaining a consistent distance from the machine’s body throughout the lifting process. The mechanism is typically achieved through hydraulic systems or mechanical linkages.

Vertical lift machines are designed to provide maximum lifting capacity in a vertical direction. They are often used in warehouses, construction sites, and other settings where materials need to be lifted to different heights. Their precise vertical movement allows for accurate positioning of the load, making them suitable for tasks that involve stacking, shelving, or moving objects to elevated platforms.

One of the main advantages of vertical lift is its versatility. The straight up and down movement enables operators to have better control and precision when handling loads. Vertical lift machines are also known for their compact size, making them suitable for tight spaces. Furthermore, they offer flexibility in terms of attachments, allowing for easy customization based on specific job requirements.

The Key Differences Between Radial and Vertical Lift

Now that we have explored the mechanisms, applications, and benefits of both radial and vertical lift, let’s summarize the key differences between these two types of lifts:

1. Movement: Radial lift machines have an arc-shaped movement, while vertical lift machines move in a straight up and down fashion.

2. Reach: Radial lift machines have a greater reach due to their arc-shaped movement, making them suitable for tasks that require extended reach or maneuverability. Vertical lift machines offer precise vertical lifting and are designed for tasks that require lifting materials to different heights.

3. Lifting Capacity: Radial lift machines generally have a higher lifting capacity compared to vertical lift machines, making them more suitable for heavy lifting tasks.

4. Power Efficiency: Radial lift machines require lesser power to operate, resulting in reduced fuel consumption. Vertical lift machines are known for their efficient use of space and versatility in tight spaces.

5. Applications: Radial lift machines are commonly used in construction, agriculture, and mining industries, while vertical lift machines are popular in warehousing, construction, and other settings.

In conclusion, understanding the difference between radial and vertical lift is essential for professionals working with machinery and equipment. These two types of lifts have distinct mechanisms, applications, and benefits. Radial lift offers an arc-shaped movement with increased lifting capacity, ideal for heavy lifting tasks in various industries. On the other hand, vertical lift provides a precise vertical movement and versatility, making it suitable for tasks that involve lifting objects to different heights.

Key Takeaways: What’s the difference between radial and vertical lift?

- Radial lift is a type of lift mechanism where the machine’s lift arms move in an arc, like a semicircle.

- Vertical lift, on the other hand, moves the lift arms straight up and down without any arcing.

- Radial lift is often used in backhoe loaders and skid steer loaders, providing increased digging power.

- Vertical lift is common in telehandlers and certain types of forklifts, providing better reach and lifting capacity.

- Understanding the difference between radial and vertical lift is important when choosing the right machine for specific tasks.

Frequently Asked Questions

Welcome to our FAQ section where we will answer your questions about the difference between radial and vertical lift. Whether you’re curious about the mechanics or the applications, we’ve got you covered. Read on to find out more!

1. How does radial lift differ from vertical lift?

Radial lift and vertical lift are two different mechanisms used in various machines, including construction equipment. The main difference lies in the direction of the lifting force. In radial lift machines, the lift force is directed towards the front of the machine, parallel to the ground. This means that when the lift arms are raised, they follow an arc that moves away from the machine. On the other hand, vertical lift machines lift vertically, perpendicular to the ground, with the lift arms moving up and down in a straight line.

The distinction between radial lift and vertical lift is crucial as it affects the machines’ capabilities in different applications. Radial lift machines are more suited for digging and lifting tasks that require reaching forward and grabbing materials, while vertical lift machines excel in tasks that require lifting materials to a higher height, straight up.

2. Which machine type is best for digging trenches?

When it comes to digging trenches, a radial lift machine is usually the more suitable choice. Due to its lifting mechanism, the arms in a radial lift machine extend further in front of the machine, enabling better reach and digging capabilities. This makes it easier to dig trenches without constantly repositioning the equipment, increasing productivity and efficiency.

While vertical lift machines can dig trenches as well, their lifting force is directed straight up and down, limiting reach. For larger and deeper trenches, the extended reach offered by radial lift machines is generally more advantageous.

3. Are there any limitations to using a radial lift machine for lifting tasks?

Radial lift machines do come with some limitations when it comes to lifting tasks. Due to their lifting mechanism, the lifting force is directed towards the front of the machine rather than straight up. This means that they may not have as much lifting capacity compared to vertical lift machines of the same size.

Additionally, the arc motion of the lift arms in radial lift machines can result in reduced stability when lifting heavy loads. It’s important to consider the weight and balance of the load being lifted to ensure safe operation and avoid tipping or loss of control.

4. What applications typically require vertical lift machines?

Vertical lift machines are often preferred in applications that require high lifting heights, such as loading material onto trucks or stacking materials vertically. The straight vertical lift ensures consistent reach and lifting capability at various heights, making them suitable for tasks like warehouse operations, construction projects, and material handling in tight spaces.

Additionally, vertical lift machines are commonly used in situations where precise positioning and control are required, such as when working with delicate or fragile materials that could be easily damaged by sudden jerky movements.

5. Can a machine be designed with both radial and vertical lift capabilities?

Yes, some machines feature a combination of radial and vertical lift capabilities. These versatile machines offer the best of both worlds, allowing operators to switch between radial and vertical lift modes based on the task at hand.

With these machines, operators have the flexibility to use radial lift for digging or reaching tasks, and then switch to vertical lift mode for lifting materials to greater heights. This versatility enhances productivity and efficiency, as the machine can adapt to various job site requirements without the need for multiple types of equipment.

Vertical vs Radial Skid Steer Explained

Summary:

So, here’s what you need to remember about the difference between radial and vertical lift. Radial lift means the arm moves in an arc, useful for digging and lifting heavy loads. On the other hand, vertical lift means the arm goes straight up and down, better for tasks like loading trucks and reaching high places. Remember, radial is like a rainbow, and vertical is like an elevator!