If you’ve ever wondered about the turning radius of a skid steer, you’re in luck! We’re here to give you the lowdown on this intriguing topic. So buckle up and get ready to explore the fascinating world of skid steers and their turning capabilities.

Skid steers are a type of compact construction equipment known for their versatility and maneuverability. But just how tight of a turn can these machines make? That’s what we’re going to uncover in this article.

So, whether you’re a curious kid who loves learning about machinery or someone with a passion for all things construction, join us as we dive into the details of the turning radius of a skid steer. Get ready for a fun and informative ride!

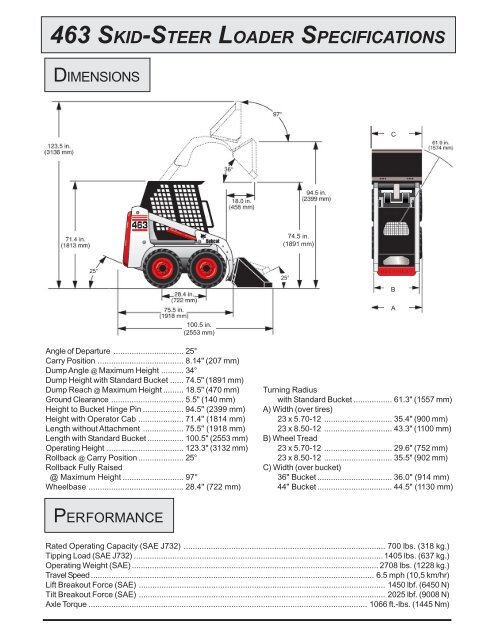

A skid steer’s turning radius refers to its ability to make tight turns. The turning radius depends on various factors, such as the size and design of the skid steer. Typically, compact skid steers have a tighter turning radius compared to larger models. To find out the specific turning radius of a skid steer, it is best to refer to the manufacturer’s specifications for the particular model you are interested in. Keep in mind that different skid steers may have different turning radii.

What’s the Turning Radius of a Skid Steer?

Skid steers are versatile machines that are commonly used in construction, agriculture, and landscaping industries. They are known for their compact size and maneuverability, making them ideal for navigating tight spaces. One important factor to consider when operating a skid steer is its turning radius. The turning radius determines the amount of space needed for the machine to make a full 360-degree turn. In this article, we will explore the turning radius of a skid steer in detail and its significance in various applications.

The Importance of Turning Radius in Skid Steers

The turning radius of a skid steer is a crucial consideration because it affects the machine’s ability to navigate efficiently and safely on job sites. Skid steers are known for their zero-radius turning, which means they can pivot within their own footprint. This allows operators to make precise turns and maneuver around obstacles with ease. However, the turning radius can vary depending on the model, tires, and operating conditions, so it’s essential to understand the specific capabilities of the skid steer being used.

Factors Affecting Turning Radius

Several factors impact the turning radius of a skid steer. Firstly, the machine’s wheelbase plays a significant role. A shorter wheelbase allows for tighter turns, while a longer wheelbase requires more space to maneuver. Secondly, the type and size of tires can affect the turning radius. Skid steers can be equipped with different tire options, such as pneumatics or solid rubber tires. Pneumatic tires offer better traction and a smoother ride but may have a slightly larger turning radius compared to solid rubber tires. Additionally, the terrain and operating conditions, such as wet or uneven surfaces, may influence the turning radius.

Other design elements, such as the geometry of the steering system, hydraulic capabilities, and the weight distribution of the skid steer, also impact the turning radius. Manufacturers optimize these factors to achieve the best balance between maneuverability and stability.

Benefits of a Smaller Turning Radius

A smaller turning radius can provide several advantages in various applications. In construction sites, where space is often limited, a skid steer with a small turning radius can navigate cramped areas without causing damage to surrounding structures. It allows operators to work efficiently in tight spots, such as narrow hallways, alleys, or between parked vehicles. In landscaping projects, a skid steer with a small turning radius allows for precise maneuvering around trees, flower beds, and existing infrastructure. The ability to make tight turns is also beneficial in agricultural operations, as skid steers can navigate between rows of crops with minimal impact, reducing the risk of damage.

Factors to Consider for Optimal Maneuverability

While a smaller turning radius is generally desirable, it may not always be the most crucial factor to consider. Operators should assess the specific requirements of the job site and choose a skid steer that offers the optimal balance between maneuverability and other essential features. Some models may sacrifice turning radius for increased lifting capacity, stability, or specialized attachments.

When selecting a skid steer, it is important to consider the intended application, available space, and other factors such as load capacity, lift height, and attachment compatibility. Additionally, operators should receive proper training and follow safety guidelines to ensure they can effectively and safely operate skid steers in various conditions.

Best Practice Tips for Maximizing Maneuverability

To optimize the maneuverability of a skid steer and make the most of its turning radius, consider the following tips:

1. Familiarize yourself with the machine:

Understanding the specific features and capabilities of the skid steer you are operating is essential. Read the manufacturer’s manual, attend training sessions if available, and familiarize yourself with the controls and functions of the machine.

2. Choose the right tires:

Select tires appropriate for the terrain and job site conditions. Pneumatic tires offer better traction but may have a slightly larger turning radius. Solid rubber tires provide better stability but may have limitations on certain surfaces.

3. Plan your route:

Prioritize planning and strategizing your route, especially in tight spaces. Identify potential obstacles or hazards and determine the best path to navigate them. This will help you avoid unnecessary turns or maneuvering and ensure efficient operation.

4. Use attachments wisely:

Attachments can alter the center of gravity and weight distribution of the skid steer, affecting its maneuverability. Consider the impact of attachments on the turning radius and adjust your approach accordingly.

5. Practice controlled and smooth movements:

Avoid sudden or jerky movements that can compromise stability and control. Practice smooth and controlled steering and acceleration to maintain balance and precision during turns.

6. Be mindful of load capacity:

Overloading the skid steer can affect its stability and maneuverability. Stay within the recommended load capacity to ensure safe and efficient operation.

By following these tips and considering the specific requirements of your job site, you can make the most of the turning radius of a skid steer and operate the machine efficiently and safely.

Key Takeaways: What’s the turning radius of a skid steer?

– Skid steers are known for their excellent maneuverability due to their compact size and unique steering mechanism.

– The turning radius of a skid steer can vary depending on factors such as the model and tire configuration.

– On average, skid steers have a turning radius of around 6 to 10 feet.

– It’s important to consider the turning radius when operating a skid steer in tight spaces or crowded areas.

Frequently Asked Questions

When it comes to skid steers, the turning radius is an important factor to consider for maneuverability. Here are some commonly asked questions about the turning radius of a skid steer.

1. How does the turning radius of a skid steer affect its performance?

The turning radius of a skid steer determines how easily and efficiently it can navigate tight spaces. A smaller turning radius allows the skid steer to make tighter turns, making it more agile and versatile in confined areas. This is particularly useful for construction sites, landscaping projects, and other work environments with limited space.

On the other hand, a larger turning radius can limit the skid steer’s ability to maneuver in tight spots, requiring more space for turns and potentially slowing down work progress. Therefore, it’s essential to consider the turning radius when choosing a skid steer for a specific task.

2. What factors affect the turning radius of a skid steer?

The turning radius of a skid steer is influenced by several factors, including the wheelbase, tire size, and hydraulic system. skid steers with a shorter wheelbase tend to have a smaller turning radius as the distance between the front and rear wheels is reduced. Smaller tire size can also contribute to a tighter turning radius, as they allow for sharper turns.

The hydraulic system plays a crucial role in the skid steer’s turning ability as well. Advanced hydraulic systems with precise control mechanisms enable smoother and more responsive steering, resulting in improved maneuverability and a smaller turning radius.

3. Is there a standard turning radius for skid steers?

No, there isn’t a standard turning radius for skid steers as it varies depending on the machine’s design and specifications. Different skid steer models offer different turning radii, and it’s important to review the manufacturer’s specifications for each specific model to determine its turning capabilities.

Keep in mind that the turning radius can also be affected by external factors such as the condition of the terrain, the load carried, and the operator’s skill in maneuvering the machine. It’s always recommended to test a skid steer in the intended working environment to assess its turning radius and overall performance.

4. How can I optimize the turning radius of a skid steer?

To optimize the turning radius of a skid steer, there are a few strategies you can employ. Firstly, using the right tire size can make a difference. Smaller tires can reduce the turning radius, allowing for tighter turns.

Additionally, maintaining the hydraulic system in good condition is essential. Regularly checking and servicing the hydraulic components, such as the steering cylinders and valves, ensures smooth and efficient functioning, contributing to improved maneuverability and a smaller turning radius.

Lastly, operator skills and experience play a significant role in maximizing the turning radius. Proper training and practice in operating a skid steer can help operators navigate the machine more effectively and utilize its full turning potential.

5. Are there any limitations to consider regarding a skid steer’s turning radius?

While skid steers are known for their versatility, it’s important to keep in mind that there are limitations to how tight their turning radius can be. The length and design of the skid steer determine its maximum possible turning radius.

Certain factors, such as attachments on the front or rear of the skid steer, can also affect its turning capabilities. For example, a longer attachment on the rear of the machine can restrict the turning radius, making it necessary to consider the overall length when navigating tight spaces.

It’s crucial to assess the specific requirements of the job at hand and choose a skid steer that offers an optimal balance between maneuverability and other necessary features, ensuring that it fits well within the available workspace.

Deere 312GR/314G/316GR/318G tight turning radius

Summary

Skid steers have a small turning radius, which makes them great for maneuvering in tight spaces. They can pivot within their own length, allowing them to get into narrow areas easily. However, the turning radius can vary depending on the specific model and the type of tires it has.

It’s important to know the turning radius of a skid steer if you’re planning to use it in a confined area or on a job site with limited space. This information will help you determine if the skid steer can navigate through doorways, around obstacles, or in other tight spots. So, before operating a skid steer, make sure to check its turning radius to ensure safe and efficient operation.